Two decades experience of producing aligner materials have provided us insight into their clinical performance. Data-driven for clinical success, we set the framework for the building blocks for the fundamentals of clinical tooth movement – the aligner material.

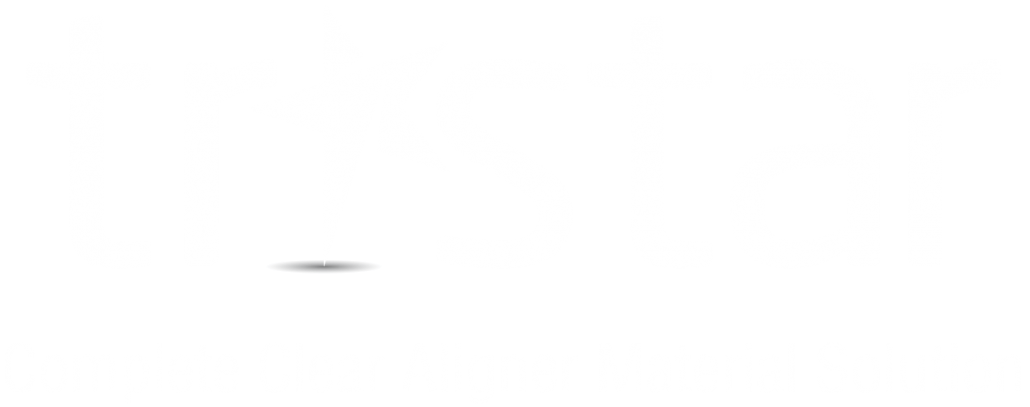

Many aligner companies, and dental clinics are using single or dual layered materials in order to perform treatment on their patients. As shown on this graphs below:

Source: Lombardo, Luca, et al. (2016). Stress relaxation properties of four orthodontic aligner materials: a 24-hour in vitro study. The Angle Orthodontist, 87(1), 11-18.

The graph above shows single layered materials – A is a polyurethane-based material, B is a single-layered Polyethylene terephthalate glycol material. Despite using different thicknesses, the graph shows that not only is the insertional force painful (at time zero), the forces decay so fast that within 5 hours only half of the force remains effective enough for tooth movement.

This is why there is significant lag – between the design of the aligner stage and actual clinical performance intraorally.

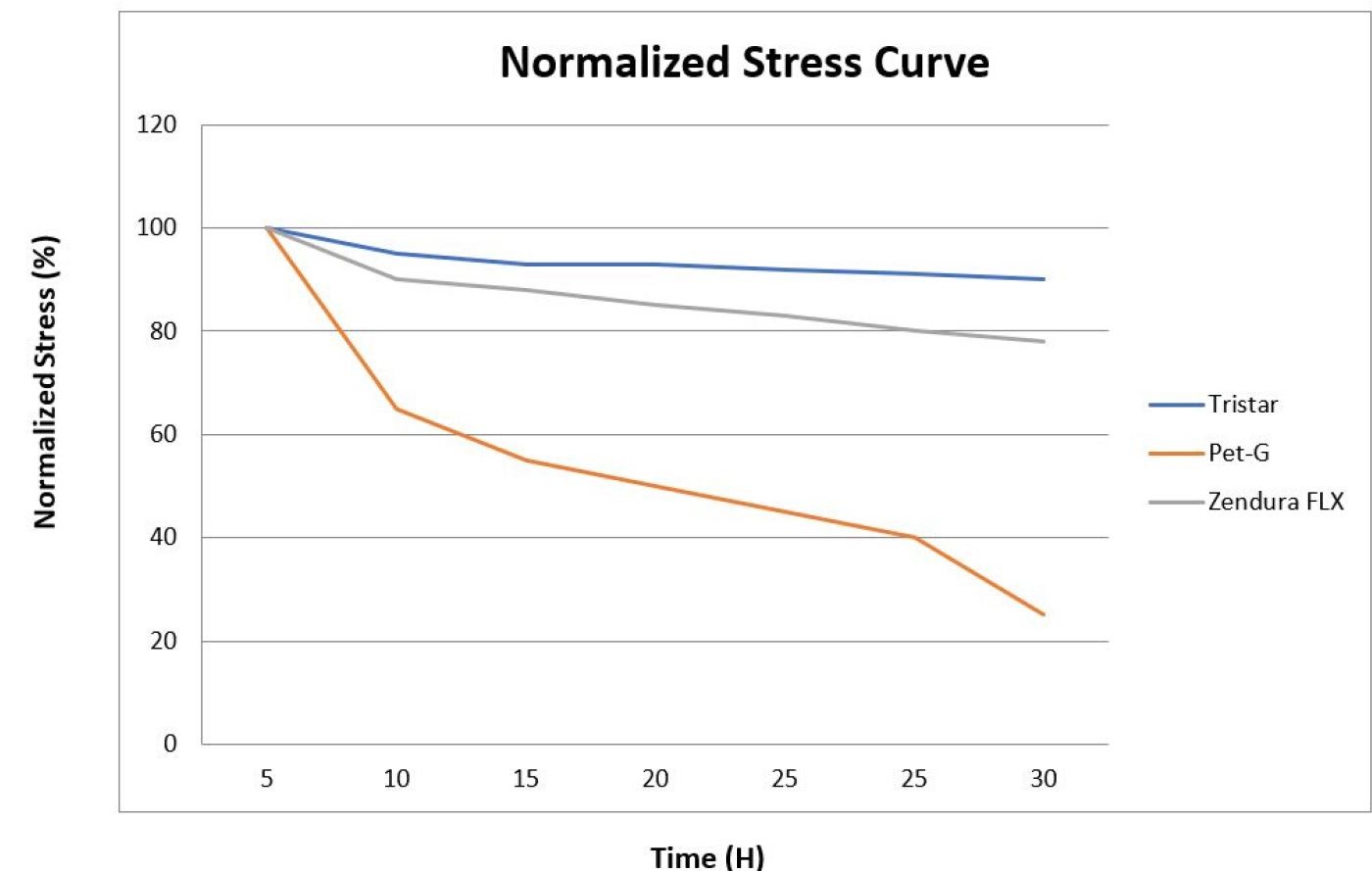

The new paradigm involves combining sheet materials – different layers that provide a strong, impact-resistant outer shell, but a soft, elastomeric inner layer. This maximises patient comfort yet ensures consistent force delivered throughout the current aligner stage. This minimizes aligner lag and maximises aligner results.

Watch how tristar performs in relation to other materials here: